Below are some excerpts for study titled “Unique Silicone-Epoxy Coatings for Both Fouling- and Drag-Resistance in Abrasive Environments” conducted by Robert Baier, Mark Ricotta, Vincent Andolina, Faraaz Siraj, Robert Forsberg, and Anne Meyer for the Center for Biosurfaces, State University of New York at Buffalo . You can read the whole study here, but the Wearlon specific points are made below.

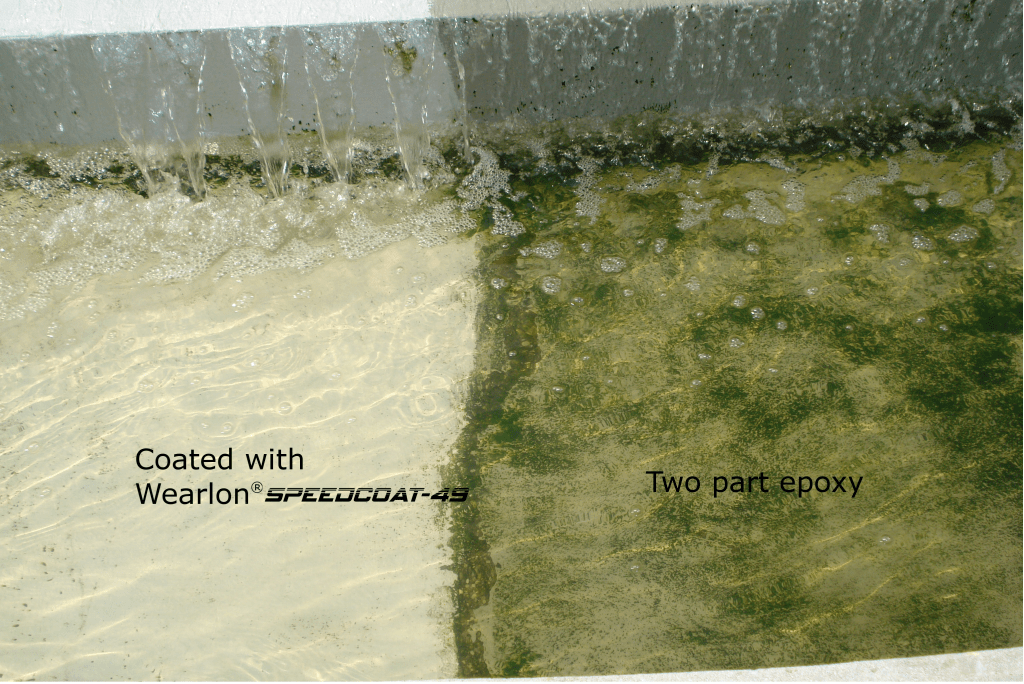

“Although prior work has led to the commercial and military acceptance of methyl-silicone-based, non-toxic and easy-release coatings (1,2) for the minimization of biofouling concerns of the world’s shipping and power industries, the best of these have proven to be too susceptible to abrasion for routine service in ice fields, dusty or turbid conditions, trash racks and turbine encasement seals—among other harsh environments. While improving the wear-resistant qualities of these coatings, one must also maintain, or improve, the drag-reduction properties (3, 4). The former coatings, when applied to racks that later were physically scraped and water-lance scoured to release accumulated zebra mussel (Dreissena sp.) debris and ice frazil required only 5psi water-lance pressure to completely clean the coatings. The underlying mechanical trash raking-induced damage to the coating was seen easily. In contrast, requiring only 50psi water-lance pressure, a specific meld of silicone and epoxy ingredients produced a hardy paint that released all debris without visual (or measured surface property) damage to the coating. Conversely, similarly challenged field-exposed trash racks fabricated from carbon-loaded high-density polyethylene, required over 2000psi water-lance pressure to remove most of their debris, always leaving behind the zebra mussel byssus threads attached by the still retained, adhesive byssus discs. Mussel byssus threads, terminated in adhesive discs, are the proteinaceous “beards” seen protruding from the shells of mussels in both seawater and fresh water. The best of the easy-release methyl-silicone-based coatings required only 5psi for complete biofouling removal, byssus discs and all other deposits, but these coatings were also the most readily abrasion damaged and released from their substrata.The intermediate 50psi fouling-release-strength coating, not as biofouling-resistant as a pure polydimethylsiloxane coating, was chosen for testing of its drag reduction properties in both stagnation point flow and as an airfoil coating in a large towing tank (3,4), and for its ease of shedding of flash-frozen ice droplets (5) in comparison with numerous comparative materials.

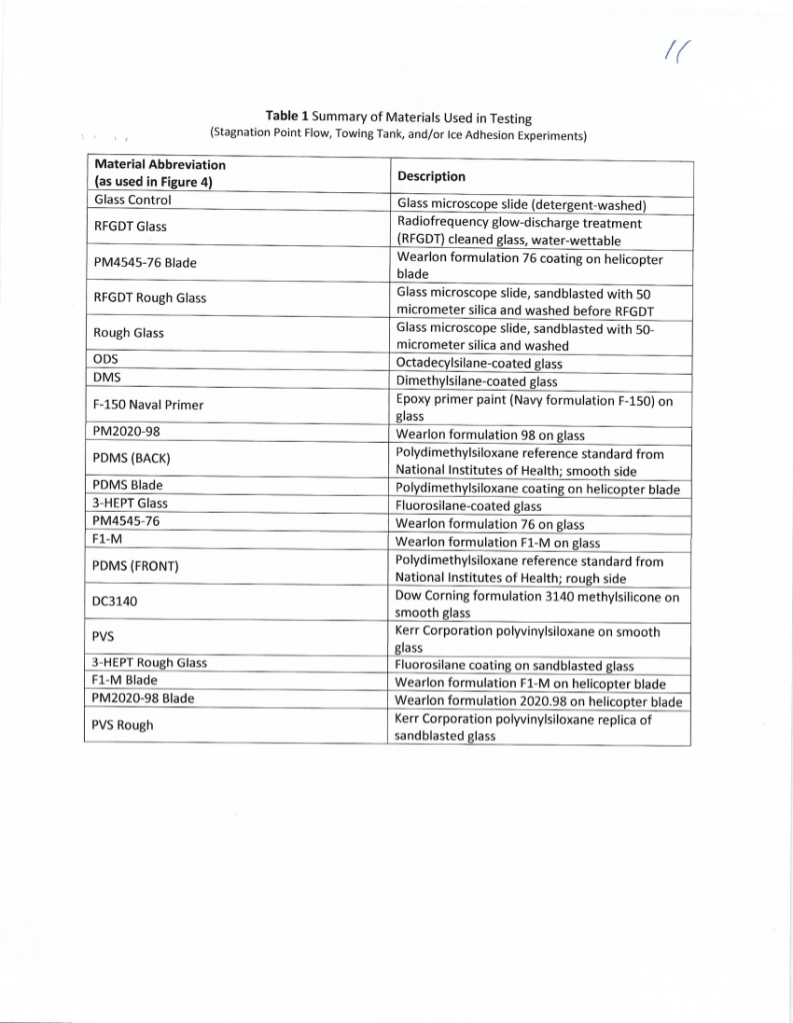

Table 1 and references (1) and (2) identify the comparative test materials. Only the coating that is the subject of this paper (Wearlon 2020.98) was demonstrably able to resist concrete, zebra mussel, and hard rubber reciprocating-seal-induced wear on cyclically operating turbine enclosures at a major power plant (6).“

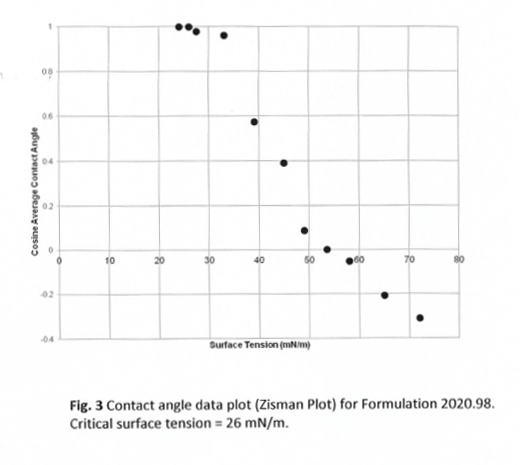

Figure 3 is a plot of the contact angle data (cosines) against the liquid/vapor surface tensions of pure diagnostic liquids, leading to an extrapolated intercept at the zero contact angle value (cos=1) of 26 mN/m, called the Critical Surface Tension (CST) by the originator of this surface characterization method (11). CST values between 20 & 30 mN/m have historically been associated with the easiest shedding of attaching biological debris at low shear stresses (12).

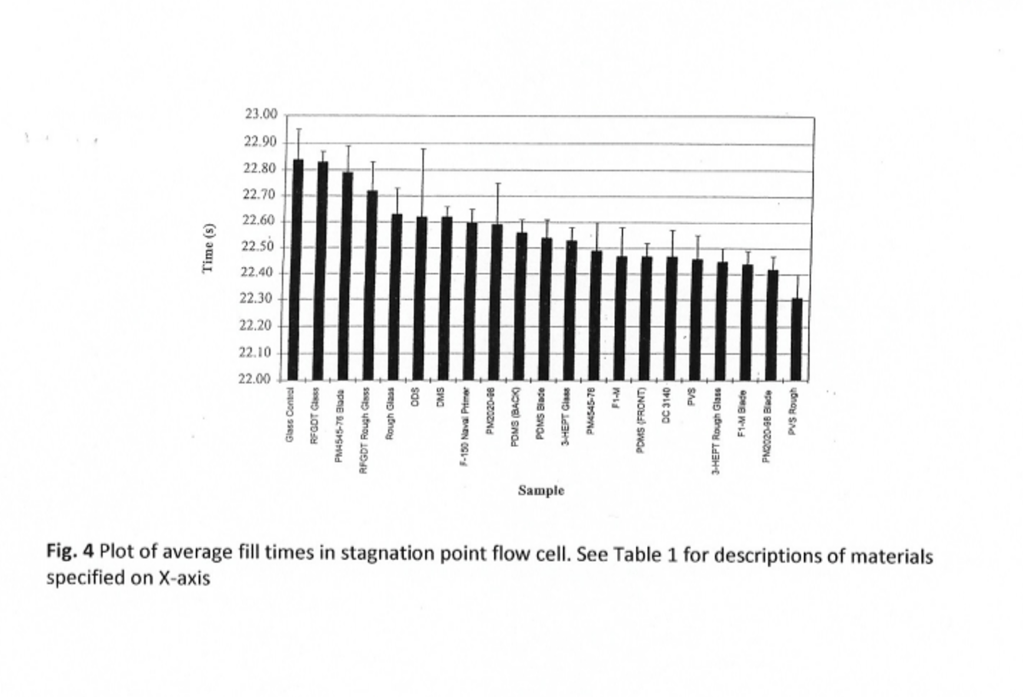

In the case of the 2020.98 formulation, vigorous wear against hard rubber and other articulation substances actually “polished” the formulation to an improved, lower-energy surface state by attacking the softer silicone-rich granules and smearing their low-energy contents over the easy-release interface. From stagnation point chamber studies, the 2020.98 formulation coatings showed the second best results in terms of minimizing flow drag of water moving from its stagnation point at 90 degrees from contact with the test surface at a constant water pressure of 27 psi, second only to a soft polyvinylysiloxane replica of roughened glass in stagnation point chamber tests of 21 different materials (Figure 4). In the water tunnel-based coated-airfoil trials, the 2020.98 formulation on airfoil rotor blades showed as much as a 5% drag reduction over the values for the clean, smooth, uncoated helicopter rotor blades (3). This exceptional effectiveness was attributed to the presence of a microscopic roughness of about 20 micrometers for the blade-applied 2020.98 surface coating, trapping water-released air bubbles in the hydrophobic micro-topographic valleys so that the actual shear took place through a water-air boundary layer of lower viscosity than wholly liquid water (4).Regarding ice adhesion studies, quantitation of attachment strength was obtained by placing 10-20 microliter droplets of water, where the water contact angles were measured in advance, onto the surfaces of well-characterized reference materials in contact with a liquid nitrogen bath, producing an average temperature approaching -20C, and then pushing off the diameter-measured droplets in accord with a published ASTM test method (5, 13), assuring that the pusher was flush with the substratum surface so that no peeling force was experienced. Characteristics of the test materials are summarized in Table 3. Again, the 2020.98 formulation gave the easiest-release values. The concurrent observation that the push-off strength was slightly lower than that for isolated polydimethylsiloxane (PDMS) was again attributed to the micro-roughness of the 2020.98 coating, trapping gas at the droplet base.Anticipating use of these coatings in newly opening Arctic shipping lanes, coated steel coupons were rotated at 60 revolutions per minute (RPM) through ice cubes piled at the air/water interface of the same device used earlier for wear testing. When the 2020.98 coating was compared with numerous coatings of the methyl silicone formulations earlier advocated (2), the paint damage was the least after equivalent icy-water passages of many miles.

“This coating has been applied to a power plant’s large intake grate (“rack”) subject to debris impact and intense zebra mussel fouling, an airfoil blade coating showing significantly lower drag than competitive paints, a turbine encasement seal layer remaining functional in zebra mussel-infested waters, and an easy-release surface for flash-frozen ice, simultaneously also resisting damage by transit through ice floes.”

Translation into Plain English: Nothing gets good adhesion to Wearlon coatings. That including algae, mussels, and ice. By rolling a Wearlon coating like SC-49 on your hull, you can greatly decrease water drag on your hull, all while decreasing the amount of slime/pond scum/fouling. And, it is long-lasting.

Fast Boats / Fuel Economy / Foul Resistant

Many marine coatings are available to boat owners. Before you invest a lot of time and money in a marine coating, you may want to try these four simple tests to determine the best undercoating for your boat. A coating that will improve fuel economy, and speed, while being resistant to fouling will be your end result.

Procedure for Preparation of the Test

Obtain a sample or swatch from the manufacturer for testing. If that is not possible, test the liquid coating by first applying a small amount as prescribed by the manufacturer and allow it to cure for at least a week prior to testing. Apply the coating to a small area of your boat or to a piece of aluminum or plastic. The best surface to allow you to see the results is a clear plastic film such as Mylar. After the coating is cured, perform the following tests.

Test #1

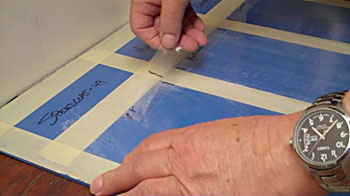

Use a small piece of adhesive tape (Scotch tape) and apply it to the coating surface and rub it with you finger. Remove it from the coated surface, and note the ease of removing the tape. Then stick the adhesive side (face-to-face) together and see if material was transferred from the coating to the adhesive. This can be determined by sticking the adhesive side face-to-face together to see if the tape has lost any of its tack or adhesion properties. If lubricants or any coating has been transferred to the tape, this means that the material will eventually end up polluting the water, as well as changing the surface dynamics of the coating.

Test #2

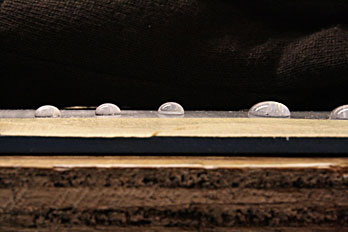

Apply a drop of water to a fresh area of the coating surface and allow standing for 5 to 30 minutes. If the water droplet flattens out after starting out as a bead of water, this coating is inferior because it shows an affinity for water that result in higher drag resistance.

After wiping off the drop of water if a milky white or colored spot is left behind where the water was applied, the coating will have inferior drag resistance through water. Initially, the boat will appear to go faster in water, but after a few runs the sacrificial lubricant will be lost and water will absorb into the coating, resulting in decreased speed because of the retained water.

Test #3

This test will evaluate hydrophobicity as a function of water drop off angle. The drop off angle is the angle that you need to tilt the coated material before the water runs off. Apply a drop of water to a fresh area of the coating and measure the initial drop off angle, as well as the height of the tilt to cause the water drop to run off. Immerse the coated material in water for at least twenty-four hours. Again, apply a drop of water to the coating and measure any change in the drop off angle. Note the trail of water left behind on the coating when tilted and rate the drop movement as follows:

Rating #1 (the worst): trail of water equals or exceeds the drop width

Rating #2: trail width is slightly less than the drop width

Rating #3: trail width is less than one-half of the drop width

Rating #4: trail width is less than one-quarter of the drop width (and the trail dissipates rapidly)

Rating #5 (the best): no trail is left behind.

Following are the results of different marine coatings as tested by an independent lab. Tests include paraffin wax, Intersleek, Wearlon, fluorinated polyurethanes, fluorinated polysiloxanes, polyamide epoxy, epoxy polysiloxane, polysiloxane/polyurethane, in modifications with molydenum disulfides:

| Drop Diameter (mm) 3 tests | Release Height (inches) | Release Angle (0 days immersion) | Release Angle (after 1 day immersion) | Drop Movement | Comments | ||

| Wearlon® | 9,9,8.5 | 3.0 | 12.4 | 16.1 | 5 | Hydrophobic | |

| Intersleek | 7,7,7 | 4.7-5.2 | 20.9 | 23.1 | 5 | Hydropphobic | |

| Paraffin Wax | 7,6,5 | 3.7-3.5 | 14.2 | 15.5 | 5 | Hydrophopbic | |

| Release Angle (After 2 days immersion) | |||||||

| Fluorinated Polyurethane | 35.4 | 58.8 | |||||

| Polyamide Epoxy (Mil-P-2441) | 46.3 | 53.2 | |||||

| Epoxy Polysiloxane | 24.8 | 47.4 | |||||

| Epoxy Polysiloxane Modified with Molydenum Disulfide | 30.0 | 48.6 | |||||

| Same as Previous but with Polysiloxane Polyurethane | 22.3 | 44.9 | |||||

| Same as Previous but with Polysiloxane | 34.2 | 54.4 | |||||

| Fluorinated Polysiloxane | 30.9 | 41.6 | |||||

| Polysiloxane Polyurethane | 32.7 | 46.0 | |||||

| Epoxy Polysiloxane | 36.4 | 41.2 |

Test #4

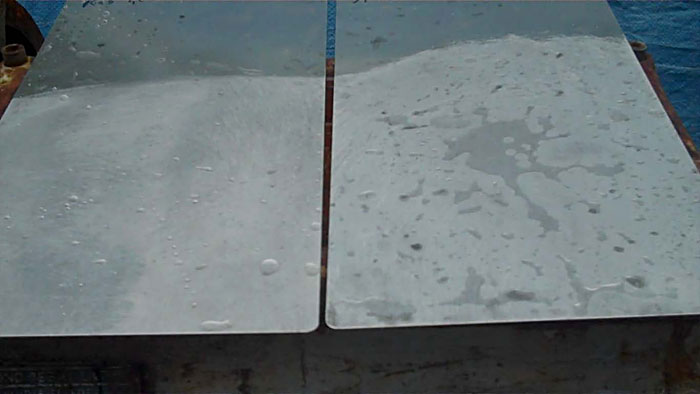

Immerse the coated substrate in water over a period of time, (one to five days should be adequate), and note upon removing from the water how the water sheds off the coating.

Using your fingernail, scratch the coating (when wet and when dry) for evaluation of the coating’s abrasion resistance. Repeat test # 1 to see if there is any change in properties after water exposure.

Conclusion

The best coating for reducing drag through water is the one that has the best contact angle with water, has excellent abrasion resistance, and remains hydrophobic while submerged in water. This allows the water to flow off your hull quickly.

These subjective tests by the mariner will quickly give him a heads-up on the best coating that can supply a clean surface (anti-fouling), provide fuel economy, reduce engine strain, and increase speed.

SPEEDCOAT-49

SPEEDCOAT-49